Classic Ore Grinding Eequipment

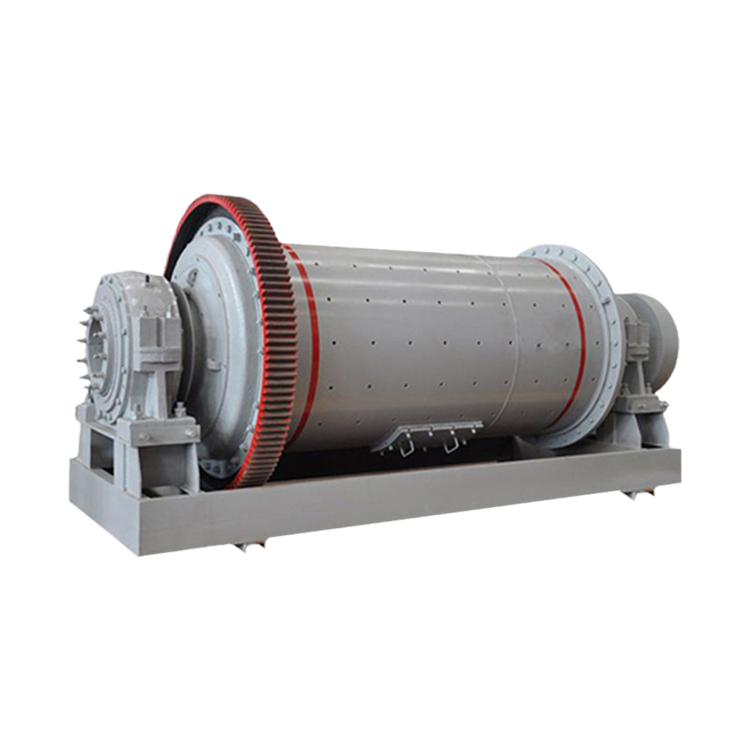

Ball Mill

-

18.5 - 1500 Kw

Power

-

2 - 260 t/h

Capacity

Description: Ball mill is widely used in cement, gold mining equipment, coal, silicate products, refractory materials, chemical fertilizers, glass ceramics and other production industries, dry or wet grinding of all kinds of ores and other grindable materials.

Model: φ1200x2400

Feeding size: ≤25 mm

Capacity: 1.5 - 5 t/h

I. What is a ball mill?

Ball mill, also named sag mill, tube mill, tumbling mill, rod mill, is the most classic mineral processing equipment to make fine powder and sand-sized granules. Ball mill has a certain number of steel balls in its drum-shaped grinding chamber as grinding medium, the materials are crushed and ground by the impact of the falling steel balls.

ball mill grinding plant

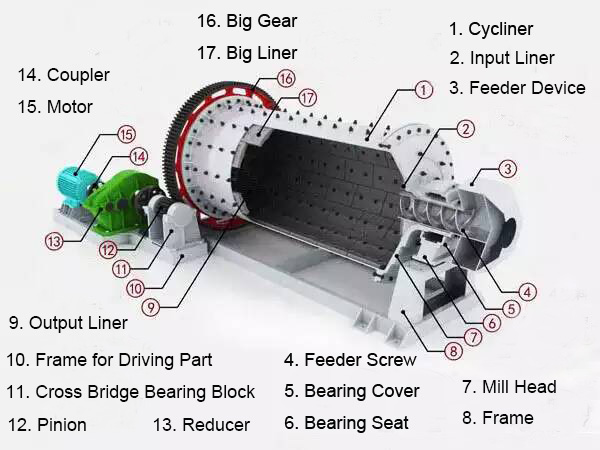

II. Ball mill working process and structure

How does a ball mill work?

1. The motor drives the ball mill to rotate through the big gear on the end of the ball mill.

2. The rotation of the ball mill generates centrifugal force, which brings the steel ball to a certain height and then falls down, which has a heavy impact and grinding effect on the material.

3. During a wet grinding process, the final product is discharged along with the flow of water. During a dry grinding process, the final product is discharged along with the airflow.

III. Cement Ball mill and ball mill with air classifier in powder industry

In cement grinding plant, ball mill is often used as cement clinker grinding mill or raw mill, the final product specific area reaches 360㎡/kg. And in minerals powder industry, ball mill equipped with an air classifier produces fine powder from 30 microns to 150 microns for materials such as limestone, calcined bauxite, silica sand, etc.

(ball mill with air classifier for 100-45 micron dry powder process) (Latest O-Sepa classifier for cement ball mill)

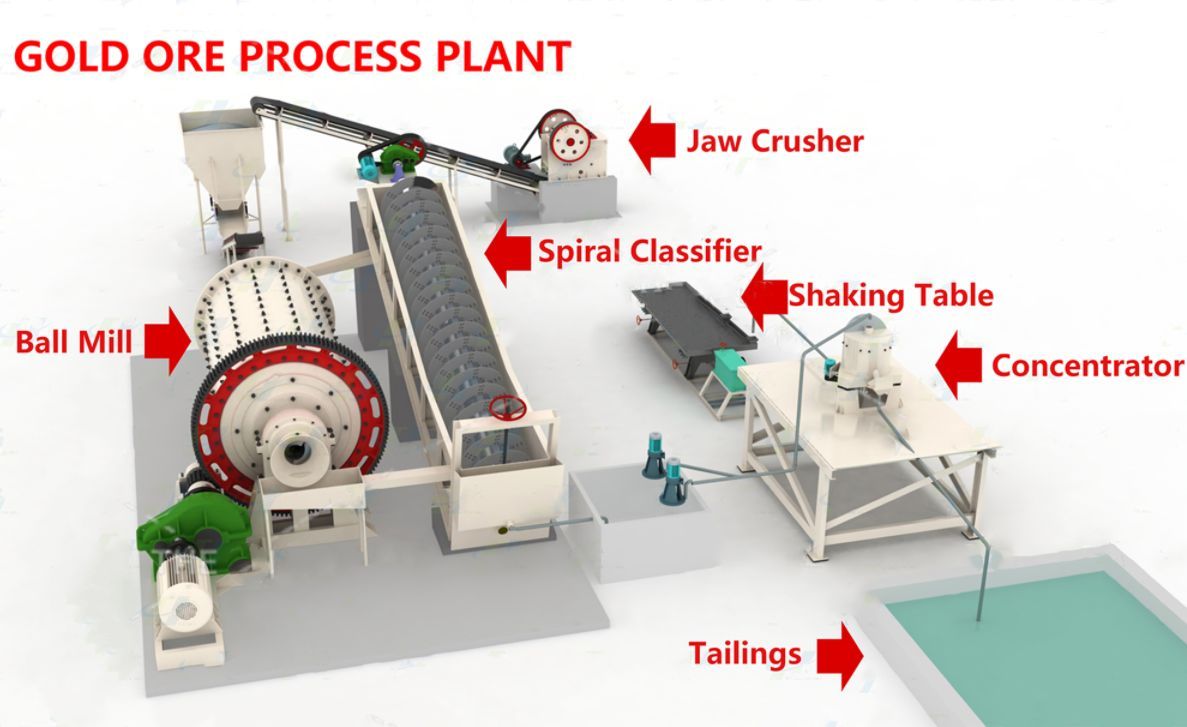

IV. Ball mill for gold mining and ore dressing

Ball mills are also used in gold ore extracting, copper refinery and other mineral dressing plant as the main size reduction equipment. In these projects, ball mill equipped with a spiral classifier. Fine particles overflows from the ball mill and enters spiral classifier to select particles that meet the fineness requirement for gravity process, flotation process or leaching tanks.

Ball mill gold gravity plant small scale

V. Contact us for quick quotation

We design and supply complete set of cement grinding plant and gold mining plant!

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat