20 - 21.5T Medium Excavator

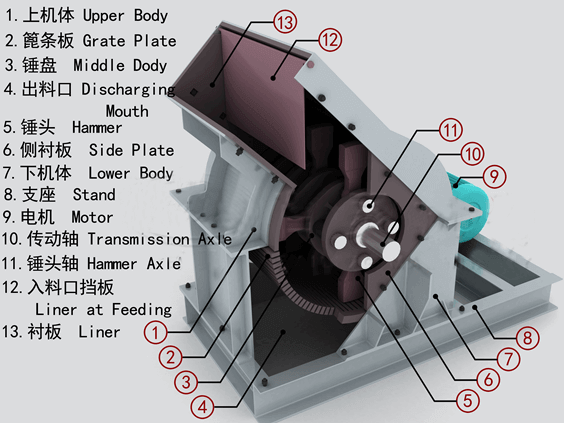

Hammer Crusher

-

104 - 125kW

Power

-

0.83 - 1.2m³

Capacity

Description: Explore the benefits of impact crushers for efficient crushing of hard and soft materials. Ideal for mining, recycling, and construction, impact crushers offer high reduction ratios, precise output sizes, and versatile applications. Learn more about featu

Model: PC-403

Feeding size: ≤200 mm

Capacity: 5-10 m³/h

I. What is a Hammer Crusher

Hammer crusher is a stone crushing equipment feeding size≤350mm, output size about 5-20mm, it mainly works as a first-stage crushing machine with lower price than a Jaw crusher, and the installation of a small scale hammer crusher is very easy, it is very suitable for investers that want a easy and quick start in mining, construction, and recycling industries field. In large projects, it is suitable for crushing of low-hardness minerals such as limestone.

Heavy-duty hammer crusher small scale hammer crusher site

II. Hammer crusher working principle and structure

Hammer crusher working process

The process begins when large chunks of material are fed into the crusher. As the hammers rotate at high speed, they impact the material with significant force, causing it to shatter. This impact generates compressive and shear forces that help reduce the size of the material further.

The crushed particles pass through a screen at the bottom of the crusher chamber, which controls the final output size. Finer particles pass through the screen, while larger pieces are redirected into the crusher chamber for further crushing.

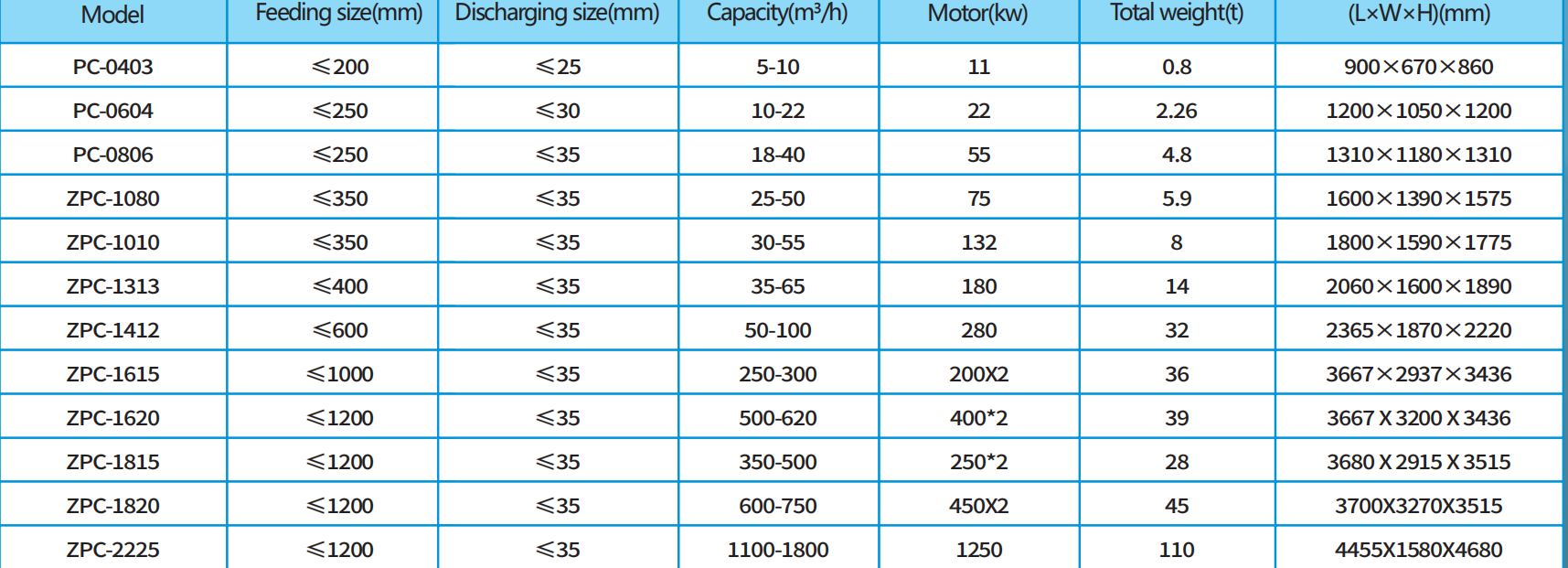

III. Hammer crusher technical parameters

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat