High-efficiency crusher for second-crushing and shaping

Impact Crusher

-

37-400 Kw

Power

-

15-680 t/h

Capacity

Description: Impact crusher is applied in stone crushing line for second-stage crushing, its final product has very good cubic shape.

Model: PF-1007

Feeding size: 300mm

Capacity: 15-30 t/h

I. What is an impact crusher?

Impact crusher is applied in a stone crushing line for second-stage crushing, giving the final product a very good cubic shape. For low-hardness stone such as limestone, the impact crusher can also be applied as the main crusher. The crushing method of impact crusher is that it uses high-speed rotating plate hammer to hit the material, then the material will be thrown onto the impact plate and be crushed.

impact crusher 3D working video

II. Impact crusher working process and main structure

impact crusher working process

1. Motor drives the belt and pulley, making the rotor rotate in high speed.

2. Material enters the crushing chamber, get hit by the plate hammer installing on the rotor, being first crushed.

3. Material is thrown, and collide with the impact plate installing on the back wall of the crushing chamber, being second crushed.

4. Material falls down from the impact plate, and collide with the material flying towards the impact plate, being third crushed.

5. Final product get discharged from the lower part of the machine.

impact crusher main structure

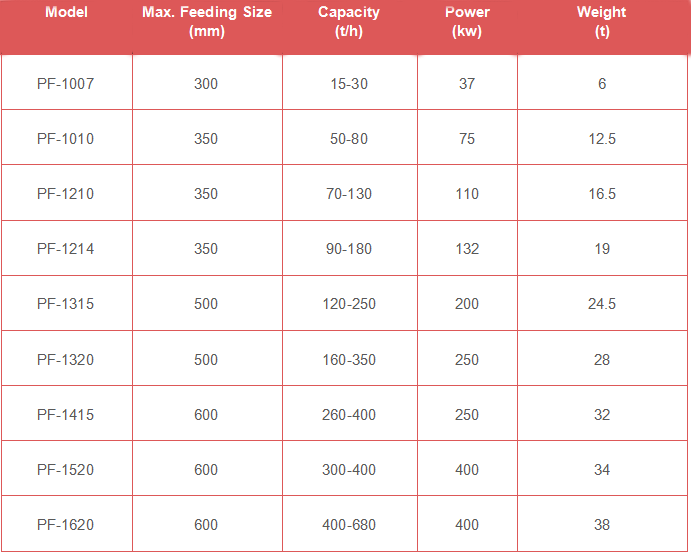

III. Impact crusher main parameters

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat