First-stage Stone Crusher

Jaw Crusher

-

5.5 - 355 Kw

Power

-

3 - 880 t/h

Capacity

Description: Powerful stone crusher for first stage crushing applicable for : Granite, quartz stone, river pebbles, calcite, concrete, dolomite, iron ore, silicon ore, basalt and other kinds of mines, rocks, slag, up to more than 200 kinds

Model: PE 250x400

Feeding size: 200 mm

Capacity: 5-20 t/h

I. What is a Jaw Crusher

The jaw crusher is a classic stone crushing equipment invented in 1858,it has two jaw plates moving close and apart, crushing big lumps of stones into smaller size. For any production line that contains stone crushing process, the jaw crusher is a maust-to-have machine to carry out the first-stage crushing task.

Jaw crusher in a stone crushing line

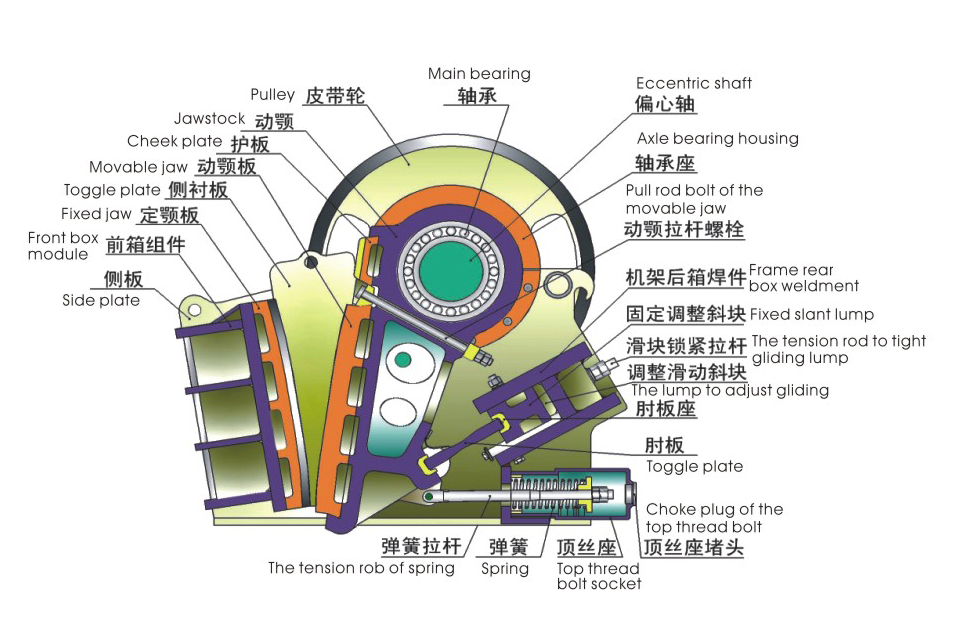

II. Jaw crusher working principle and structure

1. Motor drives the belt and pulley, making the moving jaw plate moves up and down through the eccentric shaft.

2. When the moving jaw plate rises, the moving jaw plate and the stationary jaw plate come close, and the material between the two jaw plates is crushed.

3. When the moving jaw plate goes down, the moving jaw plate leaves the stationary jaw plate, and the crushed material is discharged from the lower opening.

4. The moving jaw plate performs periodic crushing and discharging to realize big capacity crushing process.

III. Features of the jaw crusher from JHM Machinery

Large capacity

Deep “V-shape” crushing cavity design protects the machine from blockage, speed up crushing process by 30%

Durable wear parts

Jaw plates made of high-manganese-steel, enable the machine a long service when crush hard stones.

Easy operation and maintenance

Discharge opening size is adjusted by wedge

Centralized lubrication system adopted

Saving 35% operation and maintenance time

IV. Jaw crusher parameters

Related Products

Our professional team will reply to you as soon as possible.

Phone / Whatsapp / Wechat